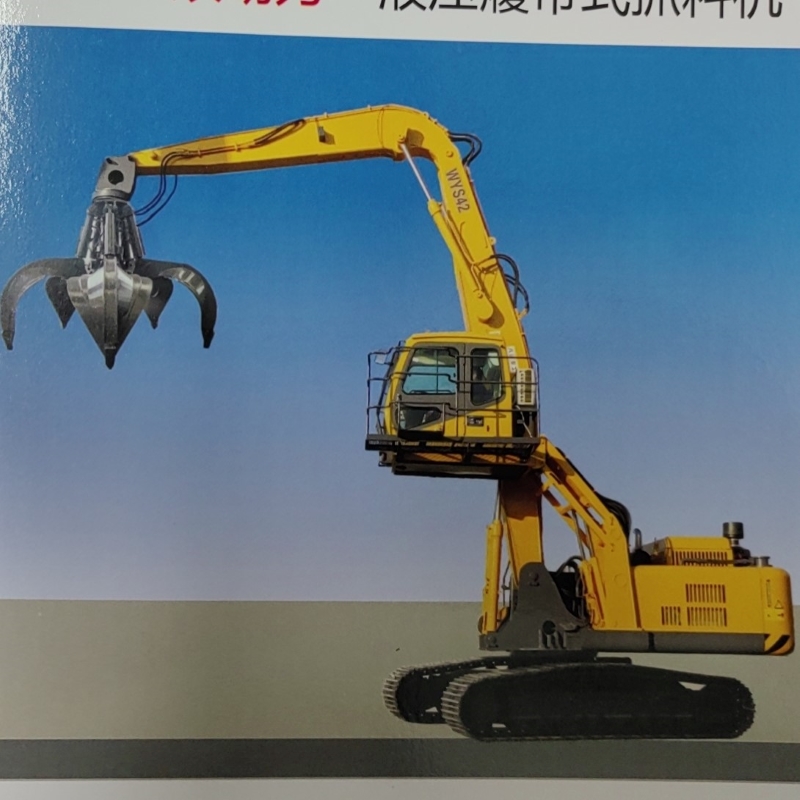

BADA WYS30 “Dual Power” Hybrid Hydraulic Crawler Material Handling Machine is a high uptime super-material handler that can meet strict operation and handling requirements in harsh environments. The unit is outfitted with a hybrid power system that combines electric and diesel engines to provide versatility, help reduce emissions, and increase fuel efficiency. The WYS30 is a rugged tracked pick & carry crane providing safe handling capabilities in challenging conditions such as construction sites, recycling plants, and industrial maintenance operations.

Features of Hybrid Hydraulic Crawler Material Handler

- Two power systems: WYS30 adopts an electric drive and a diesel walk-behind floor scrubber. This dual power arrangement enables operators to select the ideal source of energy according to their operation, which increases performance and reduces fuel costs.

- Best-in-Class Load Lift: Designed to support the lifting of heavy loads, this 6000lb capacity electric pallet jack is perfect for numerous material handling applications.

- Crawler Tracks: Crawler tracks give the machine immense stability and maneuverability across uneven and rough terrains, ensuring consistent performance in complex environments.

- The high-pressure capabilities of the advanced hydraulic system on WYS30 deliver a precise, controlled response for ease in operating movements. It also automates process operations and reduces the scope for human errors, which simplifies complex jobs.

- Eco-friendly: The hybrid powertrain reduces fuel use and emissions. Additionally, the electric engine alternative decreases functional sound for a much more silent working site and less environmental impact.

Applications of WYS30 “Double Power” Hybrid Hydraulic Crawler Material Handling Machine

- Construction Sites—It is perfect for holding and moving heavy construction materials such as steel beams, concrete blocks, or large pipes. Its high lifting capacity and stability make it an essential asset on any construction site.

- Recycling Facilities: These work best for handling and sorting large quantities of recyclable materials such as scrap metal, plastics, or paper. Its precision and efficiency contribute to optimizing recycling processes within a machine.

- Industrial Applications include lifting and moving heavy machinery, transporting bulk materials, and managing stock. Utility Operations Include Providing energy during blackouts across the oil and gas industry.

- Port and Dock Operations: This machine is needed to handle cargo at ports and docks, such as loading or unloading ships, moving containers, and stacking many things. Its good ground clearance, mobility, and high lift capacity allow it to perform highly efficient port operations→Efficient navigation at ports due to its low height.

|

Power

|

Engine

|

118kW

|

|

Electric Motor

|

75kW

|

|

Fuel tank

|

320L

|

|

Walking system

|

Walking speed

|

2.5/5.0km/h

|

|

Max. traction force

|

150KN

|

|

Gradability

|

25%

|

|

Hydraulic system

|

Max. flow

|

2*160L/min

|

|

Max. working pressure

|

29Mpa

|

|

Hydraulic oil tank

|

320L

|

|

Pilot pressure

|

3.8Mpa

|

|

Main performance parameter

|

Total weight

|

25.5t

|

|

Max. Lifting moment

|

60t.m

|

|

Max. swing speed

|

8r/min

|

|

Max. swing torque

|

75KN.m

|

①WYS Series hybrid hydraulic crawler material handler produced by Bada Heavy Industry can be equipped with driving systems of diesel driven, electric driven or “Dual-Power” mixing fuel and electric driven. It is with reliable quality, superior performance and can service several purposes.

● World-class and well-known brands are selected and used for all main parts.

●High-strength steel is used for all crane arm assembly and key steel structure.

●World-leading “dual-power” drive technology with over 20 years of experience, unmatched, safe and reliable.

●The world’s leading “dual-power” driving technologyover 20 years’ experience, unparalleled, safe and reliable.

● World-leading hydraulic system: ①Dual power drive, dual pump dual circuit total power adjustment, negative flow control open system; ②Dual power drive , dual pump dual circuit power control,Open system with pilot pressure override, positive flow control.

● Other grippers can be easily replaced to carry out gripping and releasing operations on various raw materials; after removing the grippers, it can be used as an ordinary crane, so one machine can have multiple uses.

● Equipped with independent hydraulic cooling system to ensure stable oil temperature during continuous operation.