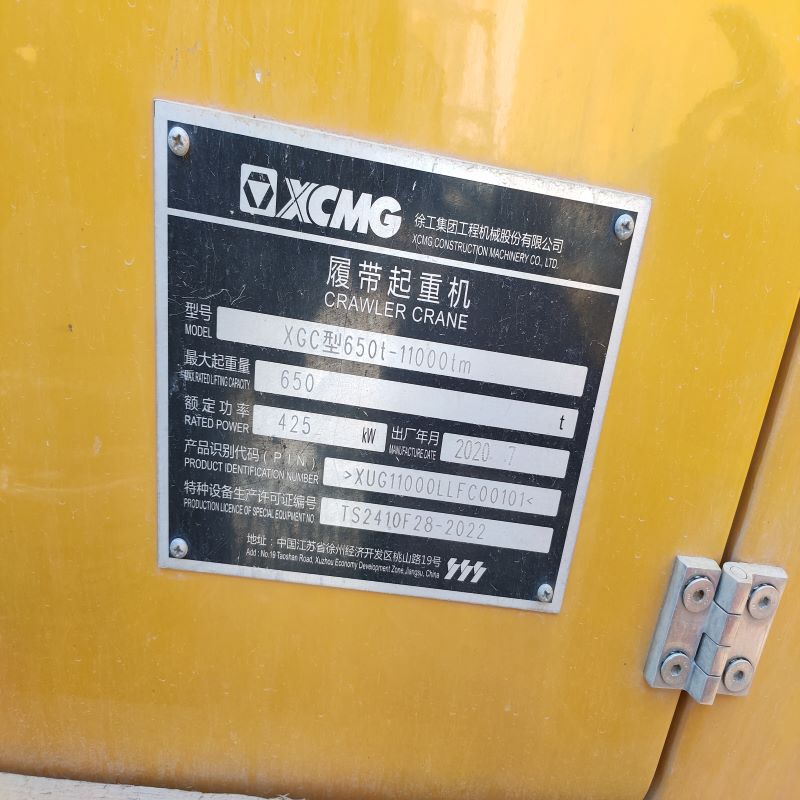

The Used XGC11000 Lattice Crawler Crane is a heavy-capacity, multi-functional crane that makes those difficult lifts easier. Designed and developed by XCMG, a leading name in the construction machinery business, this crane model is popular for its excellent lifting capacity property alongside advanced features and strong build quality. Designed to tackle a diverse range of industrial applications, the XGC11000 is an invaluable asset for practically any heavy-duty lifting fleet. The world’s first 11000-ton crawler crane, XCMG XGC11000, is designed to tackle the most challenging environments with its precision-focused structure and exceptional performance.

Key Features of Used XGC11000 Lattice Crawler Crane

- Max Lifting Load Moment: The crane features a maximum lifting load moment of 10800 t.m, providing exceptional lifting power for the heaviest and most demanding tasks. This significant lifting capacity ensures that the crane can handle large and heavy components with ease and precision.

- Standard Working Condition Heavy Duty Boom: The XGC11000 is equipped with a heavy-duty boom that ranges from 24 to 96 meters. This extensive boom length provides the flexibility to perform various lifting operations, making it suitable for a wide range of applications.

- Standard Working Condition Light Duty Boom: The light-duty boom ranges from 66 to 108 meters, offering enhanced reach and flexibility for lighter lifting tasks. This configuration allows the crane to adapt to different lifting requirements, enhancing its versatility and efficiency.

- Standard Working Condition Tower Jib: The crane features a tower jib that ranges from 30 to 66 meters. This configuration provides additional reach and lifting capacity, making it ideal for tasks that require height and precision.

- Advanced Hydraulic System: The state-of-the-art hydraulic system ensures smooth and precise operation, enhancing the crane’s efficiency and reducing operator fatigue. This system is critical for maintaining control and precision during complex lifting tasks.

Applications of Used XGC11000 Lattice Crawler Crane

The Used XGC11000 Lattice Crawler Crane is highly versatile and can be used in a wide range of applications, making it an invaluable asset for various industries.

- Power Plant Construction and Maintenance: The XGC11000’s significant lifting capacity and precision make it ideal for the construction and maintenance of power plants. This includes the installation of large components such as boilers, condensers, and reactors, ensuring that these critical elements are positioned accurately and securely.

- Steel Structure Erection: The crane is highly effective in the erection of steel structures, where it can lift and position large steel beams and girders with precision. This is particularly useful in constructing commercial buildings, stadiums, and large industrial facilities.

- Infrastructure Development: The XGC11000 can be employed in various infrastructure projects, including the construction of highways, railways, and airports. Its ability to handle heavy loads and reach significant heights makes it ideal for placing large structural components and assemblies.

- Heavy Equipment Relocation: The crane’s lifting capacity and mobility allow it to relocate heavy machinery and equipment within industrial sites. This is beneficial for plant reconfigurations, expansions, or routine maintenance tasks.

- Demolition Projects: While primarily designed for construction, the XGC11000 can also be utilized in demolition projects where controlled dismantling of large structures is required. Its precision and power ensure that such tasks are carried out safely and efficiently.

|

Items

|

Data

|

|

Standard

working

condition

|

Heavy duty boom working condition

|

650t

|

|

Light duty boom working condition

|

330t

|

|

Tower jib working condition

|

230t

|

|

Wind power jib

|

165t

|

|

SL working

condition

|

Heavy duty boom working condition

|

650t

|

|

Light duty boom working condition

|

240t

|

|

Light duty boom working condition

|

254t

|

|

Tower jib working condition

|

360t

|

|

Wind power working condition

|

170t

|

|

Wind power working condition

|

240t

|

|

Wind power working condition

|

165t

|

|

Max. lifting load moment

|

10800t.m

|

|

Size and

parameters

|

Standard workig

condition

|

Heavy duty boom working condition length

|

24~96m

|

|

Light duty boom working condition length

|

66~108m

|

|

Tower jib working condition length

|

30~66m+24~96m

|

|

Wind power jib boom length

|

78~102m

|

|

SL working

condition

|

Heavy duty boom working

condition length

|

48~114m

|

|

Light duty boom working

condition length

|

114~147m

|

|

Light duty boom working

condition ength

|

126~165m

|

|

SL tower jib working

condition length

|

40~108m+24~96m

|

|

Wind power working

condition boom length

|

96~147m

|

|

Wind power working

condition boom length

|

96~168m

|

|

Wind power working

condition boom lengt

|

126~165m

|

|

Wind power jib length

|

12m

|

|

Speed

parameters

|

Max. single line speed for hoisting

|

130m/min

|

|

Max. single line speed for boom luffing

|

2*56m/min

|

|

Max. single line speed for hoisting

|

130m/min

|

|

Max. slewing speed

|

0.7rpm

|

|

Max. travel speed

|

1.0km/h

|

|

Engine

|

Rated power

|

420kw

|

|

Emission standard

|

EUROⅢ

|

|

Overall crane weight

(based on 34m heavy duty boom,700t)

|

496t

|

|

Average ground pressure

|

0.146MPa

|

|

Gradeability

|

10%

|

|

Max. single unit transport weight

|

71t

|

|

Max. single unit transport size(L×W×H)

|

12m*3.3m*3.4m

|

Product Highlights and System Description

Standard working condition

- HB:standard working condition heavy duty boom, 24~96m,10.5m boom butt×1, 6m insert section×2, 12m insert section A×1, 12m insert section B×2, 12m insert section B-center hitch×1, 12m thin wall insert section C×1, 12m tipper section ×1, 1.5m boom head ×1.

- LB:standard working condition light duty boom, 66~108m,5m boom butt×1, 12m boom insert B×2, 12m insert B-center hitch×1, 12m tipper section×1, 12m tower jib section A×1, 6m tower jib section ×2, 12m tower jib section B×2, 7.5m tower jib top section ×1.

- WJ:standard working condition tower jib, when boom length is 30~66m, tower jib 24~84m can be added, 4.5m tower jib butt×1, 6m tower jib insert section×2,12m tower jib thick wall insert section A×1, 12m tower jib thick wall insert section B×2,12m tower jib thin wall insert section C×2,7.5m tower jib top section ×1.

- HJ-S3:standard working condition wind power jib, when boom length is 78~102m,wind power jib can be added. 10.5m boom butt×1, 12m transition section I (strengthened) ×1 , 12m insert section (strengthened) ×1,12m transition section II (strengthened) ×1 , 3m insert section×1,6m insert section×1,12m insert section A×1,12m boom insert section B×2, 12m boom center hitch section B×1, 12m tipper section ×1,12m tower jib thick wall insert section A×1, 7.5m tower jib top section×1. Wind power jib is 12m×1.

SL working condition

- SHB-S7 SL working condition heavy duty boom : optional boom length is 36 ~ 114m , its composi-tion:10.5m boom butt×1,12m transition section I (strengthened) ×1 , 12m heavy duty section (strength-ened) ×1, 12m insert section (strengthened) × 4,12m transition section II (strengthened) ×1, 6m insert section×1, 12m tipper section ×1, 1.5m boom head ×1.

- SLB-S7 SL working condition light duty boom : optional boom length is 114~147m, its composition: 10.5m boom butt×1, 12m transition section I (strengthened) ×1, 12m heavy duty boom (strengthened) ×1, 12m insert section (strengthened) ×4, 12m transition section II (strengthened) ×1, 3m insert section ×1, 6m insert section ×1, 12m insert section A×1, 12m insert section B-center hitch ×1,12m tipper section ×1, 7.5m tower jib head ×1.

- SLB-TS4 SL working condition light duty boom: optional boom length is 126~165m, its composition: 10.5m boom butt ×1, 3m connection section I ×1, 10.5m larger cross section boom I×2,light duty larger cross section boom II ×2, 3m connection section II×1, 12m insert section (strengthened) × 4, 12m transi-tion section II (strengthened) ×1, 3m insert section ×1,6m insert section ×1,12m insert section A×1, 12m tipper section ×1, 7.5m tower jib head ×1.

- SWJ-S7 SL working condition tower jib: when boom length is 48 ~ 108m , tower jib 24~96m can be added, 4.5m jib butt ×1, 6m tower jib insert section ×2, 12m tower jib thick wall insert section A×1, 12m tower jib insert section B×2, 12m tower jib thin wall insert section C×3, 7.5m tower jib top section ×1.

- SHJ-S7 SL working condition wind power jib: optional boom length is 96~147 m,wind power jib 12m, its composition: 10.5m boom butt×1,12m transition section I (strengthened)×1 12m heavy duty section (strengthened) × 1, 12m insert section (strengthened) × 4, 12m transition section II (strengthened) × 1, 3m insert section × 1, 6m insert section × 1, 12m insert section A×1, 12m insert section B-center hitch×1, 12m tipper section × 1, 7.5m tower jib head×1, 12m wind power jib assembly ×1.

- SHJ-S9 SL working condition wind power jib:optional boom length is 96~168m, wind power jib 12m, its composition: 10.5m boom butt × 1, 12m transition section I (strengthened), 12m heavy duty section (strengthened) ×1, 12m insert section (strengthened) ×1,12m transition section II (strengthened),3m insert section×1, 6m insert section×1, 12m insert section×1,12m boom center hitch section B×1, 12m tipper section ×1, 7.5m tower jib top section×1. Wind power jib is 12m×1.

- SHJ-TS4 SL working condition wind power jib: optional boom length is 126~165m, wind power jib 12m, its composition: 10.5m boom butt × 1, 3m connection section I × 1, 10.5m large cross- section boom I ×2, light duty large cross-section boom II × 2, 3m connection section II×1, 12m insert section (strengthened) ×4, 12m transition section II (strengthened) ×1, 3m insert section ×1, 6m insert section ×1, 12m insert section A×1,12m tipper section ×1, 7.5m tower jib head×1, 12m wind power jib assembly ×1.

Boom luffing components

Boom luffing component is composed of two-group pendant , made of high-strength steel and one – time cutting; with high safety factor. Pendants are equipped with balance beam, effectively keep the two groups of pendants in balance state and even force bearing.

Mast

Mast is box-type of twin limb structure, with additional beam between two limbs for good overall stability. Mast is equipped with raising device; SL mast is equipped with automatic backstop system. Standard type mast can be used as temporary boom to realize self-assembly/dismantling of crawler track and boom.

Turntable

Turntable is box type structure made of domestic high-strength steel plate, connected with “工” type and box type beam in the middle of it, and arranged with reinforced plate near the slewing center.

Hoist winch

- Turntable is box type structure made of domestic high-strength steel plate, connected with “工” type and box type beam in the middle of it, and arranged with reinforced plate near the slewing center.

- Main hoist winch rope, rope diam.φ28 mm;

- Main hoist winch rope, rope diam.φ28 mm;

Boom luffing winch

- Boom luffing winch is a twin drum independent drive unit, with ratchet locking device, built-in speed reducer, and disc type constant closed brake. rope diam. φ 28 mm.

- Super-lift luffing winch has ratchet locking device, built-in speed reducer, and disc type constant closed brake.

- rope diam. φ 28 mm.

Slewing gear

Slewing gear is arranged at front of turntable and made of two planetary reducers , external engagement with slewing bearing with hydraulic buffering device and sliding function, and controllable constant-closed disc brake for the function of free-swing. Reliable working and easy maintenance.

Slewing ring

Slewing ring is 3-row roller type external meshed slewing ring , with high strength , heavy load bearing capacity , and easy for repair and maintenance.

Oil cylinder assy

Slewing ring is 3-row roller type external meshed slewing ring , with high strength , heavy load bearing capacity , and easy for repair and maintenance.

Operator’s cabin

Operator’s cabin is ergonomic design, wide vision, comfortable and convenient operation.

when the crane is in transport, the operator’ s cabin can be turned 90° to the front of turntable (boom base removed) so as to reduce transport width;

when the crane is in operation, the operator’s cabin can be tilted upward 20° for high level vision.

Car-body

Car-body is made of high-strength steel and welded in box type structure, with cross panel installed in the middle to strengthen its stiffness against torsion, simple structure, high loading capacity and good rigidity.

Track frame

Crawler travel unit consists of track frame, track shoe , track roller, drive sprocket , idler roller and travel motor.

Track frame is box-type structure , the connection place to frame is partially strengthened , with cross panel installed in the middle of it.

Two crawler tracks are symmetrically arranged , equipped with track board with width of 1.5m, can be operated synchronously or independently to achieve straight drive and turning around. Crawler travel unit has German imported built-in planetary reducer and driven by variable motor.

Hydraulic System

Combination of closed/open type system with electronic proportional pilot control and variable displacement pump system, good system stability and fine speed regulation.

Combination of closed/open type system with electronic proportional pilot control and variable displacement pump system, good system stability and fine speed regulation.

Slewing gear is closed type pump control system, no need of balance valve and change valve, smooth drive and no impact.

Variable displacement motor drive is used for main/auxiliary hoist winch and travel unit with large range of speed regulation. Variable displacement motor + variable displacement pump control system can have accurate regulation for movement speed, and with good fine motion.

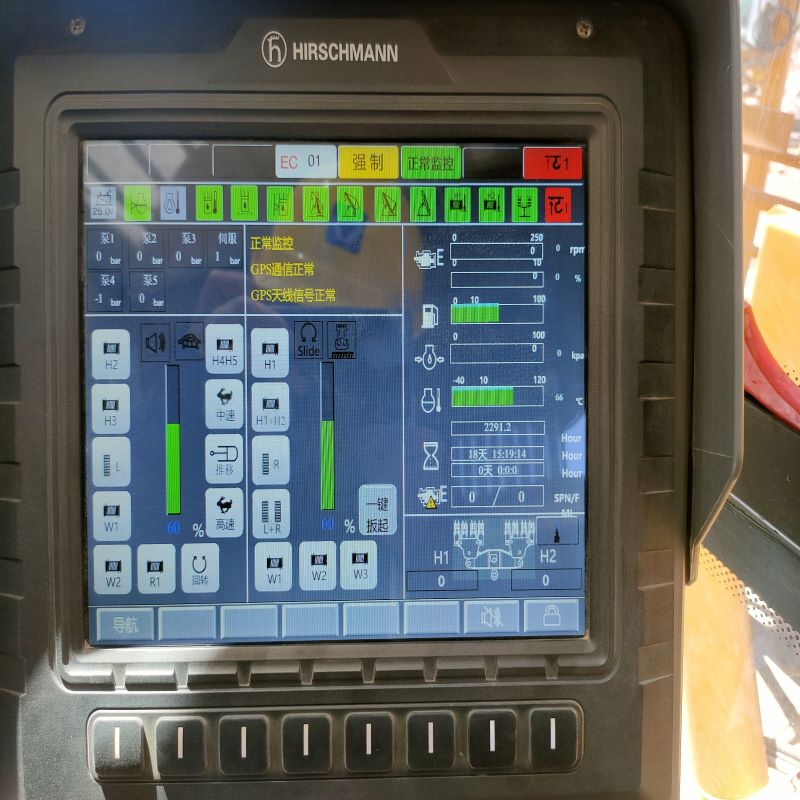

Electrical System

Electrical system mainly includes: operation control and safety monitoring for engine, instrument, auxiliary equipment, hydraulic system and load moment limiter.

Electrical system composition: conventional electric system and PLC monitoring system.

Conventional electrical system including power supply, start control, engine control and state monitoring, cabin air-conditioner and acoustics, illumination (lamp), rain wiper, and interphone.

PLC control system includes main/auxiliary winch, slewing gear, boom luffing, left/right crawler travel, cabin rotation/tilting. All movements use electro-hydraulic proportional control technology, and with PLC logic control.

Engine System

Manufacturer: famous brand, turbocharged, inter-cooled and electronic injection;

Environmental: comply with Euro III emission regulation;

Fuel tank capacity: 700L

Hook Block

700T,500T,240T,16T

Notes: 700t hook is a combination hook, which can be disassembled into 350t hook.

500t hook is a combination hook, which can be disassembled into 250t hook.

240t hook is a combination hook, which can be disassembled into 100t hook.

Scope of supply according to actual condition.